Securing container safety

The TopTier project started in May 2021. By mid 2022, the project is supported by 40 participants including 3 national authorities, 10 major carriers, 7 class societies and 5 lashing manufacturers.

The TopTier joint industry partnership (JIP) is a project focused on the loss of containers at sea. The size of deep sea container ships has increased significantly over the past years. The loss of containers and their impact on the maritime and coastal environments has raised public and political concerns on the safety and environmental impact of modern container ships. Authorities and industry are urged to evaluate container securing and improve regulations and practices to avoid such losses of containers at sea. TopTier was initiated to address these topics with active participation of major stakeholders.

Phase 1

Phase 1 of the project reviewed current practice and incidents and identified gaps. Several successful meetings took place and three reports were submitted for review. This phase was concluded with three early deliverables to alert mariners to the particular phenomena of parametric roll in following seas conditions.

Phase 2

From mid-2022, work started on Phase 2 of the project. Six working groups are currently undertaking detailed technical research and investigations. These working groups contribute to the overall project goal with targets that are complementary. The outputs will be combined into practical safety improvements during Phase 3 of the project.

Working groups

Group 1

Containers and gear

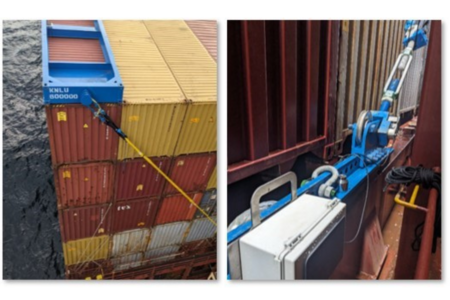

Group one aims to understand the limits and uncertainties of containers and lashing gear. This group is currently undertaking basic material tests recognising that containers will be presented in a variety of conditions due to wear and tear and damage. Future work following material tests will include numerical simulations to determine safety margins for container buckling (racking) and combined container and lashing gear.

Group 2

Loading logistics

Group two will outline uncertainties in true stow configuration versus planned stow configuration. The group will; research and demonstrate the impact of mis-stowed containers on the stability of the stack and whole, assess the estimated mis-stow rate, the weight deviations, the potential impact on stability and understand the underlying reasons.

Studies to date suggest that the percentage of mis-stowed loaded containers on deck ranged from 0% to 92%, that there are large weight deviations as a result ranging from 38% to 236%. The average per ship of mis-stowed containers was calculated to be 10%. Recognition that not all required stakeholders are currently represented in the TopTier project, namely the ship to shore interface, terminals in particular have no representation.

Group 3

Vessel motions

Group three aims to understand and predict both in and out of design motions and conditions for securing requirements. Study is based on a 10,000 TEU ship. They are exploring the possibility of avoiding incidents with additional onboard support and considering and modelling parametric rolling motion.

Tests to date suggest that it is possible to avoid critical roll conditions, providing that perfect onboard advisory, including weather forecast (including wind sea and swell height, period and direction) reliable limits in the roll risk estimator (including limiting wave height) and reliable roll period measurement and prediction. Simply avoiding a predetermined wave height is also possible, however substantially increases the required rerouting distance. Creating a 15,000 TEU model ship for further testing.

Group 4

Securing loads

The aim of working group 4 is to understand the actual forces and loads for given motions and stow configurations. Model testing is focused on stacking and racking strengths through various stack configurations. Further model testing to be undertaken by the group in future.

Group 5

Decision support

The decision support group aims to highlight what is required to operate the vessel to stay inside design motion envelope.

Can assistance be given to the crew to aid navigation decisions?

Their focus is on keeping the ship within “in design” conditions and preventing exposure to “off design” conditions. This would include loading and lashing calculations, route planning and response based weather routing, response forecast and monitoring of motions (waves etc). The group is focused on whether it is possible to recognise, act and prevent parametric rolling.

Group 6

Regulatory aspects

The final group is working to anchor good practice in the relevant regulatory framework (IMO/Flag state/Class). This group presented an update on the JIP at MSC106. The IMO secretariat have since formally joined the project to assist in the delivery of outcomes and recommendations.

There is aspiration to deliver an annual update to the most appropriate IMO committee, which has been suggested to be Carriage of cargoes and containers (CCC).

The TopTier project started in May 2021

By mid-2022, the project was supported by 40 participants including 3 national authorities, 10 major carriers, 7 class societies, 5 lashing manufacturers, IGP&I and TT Club.