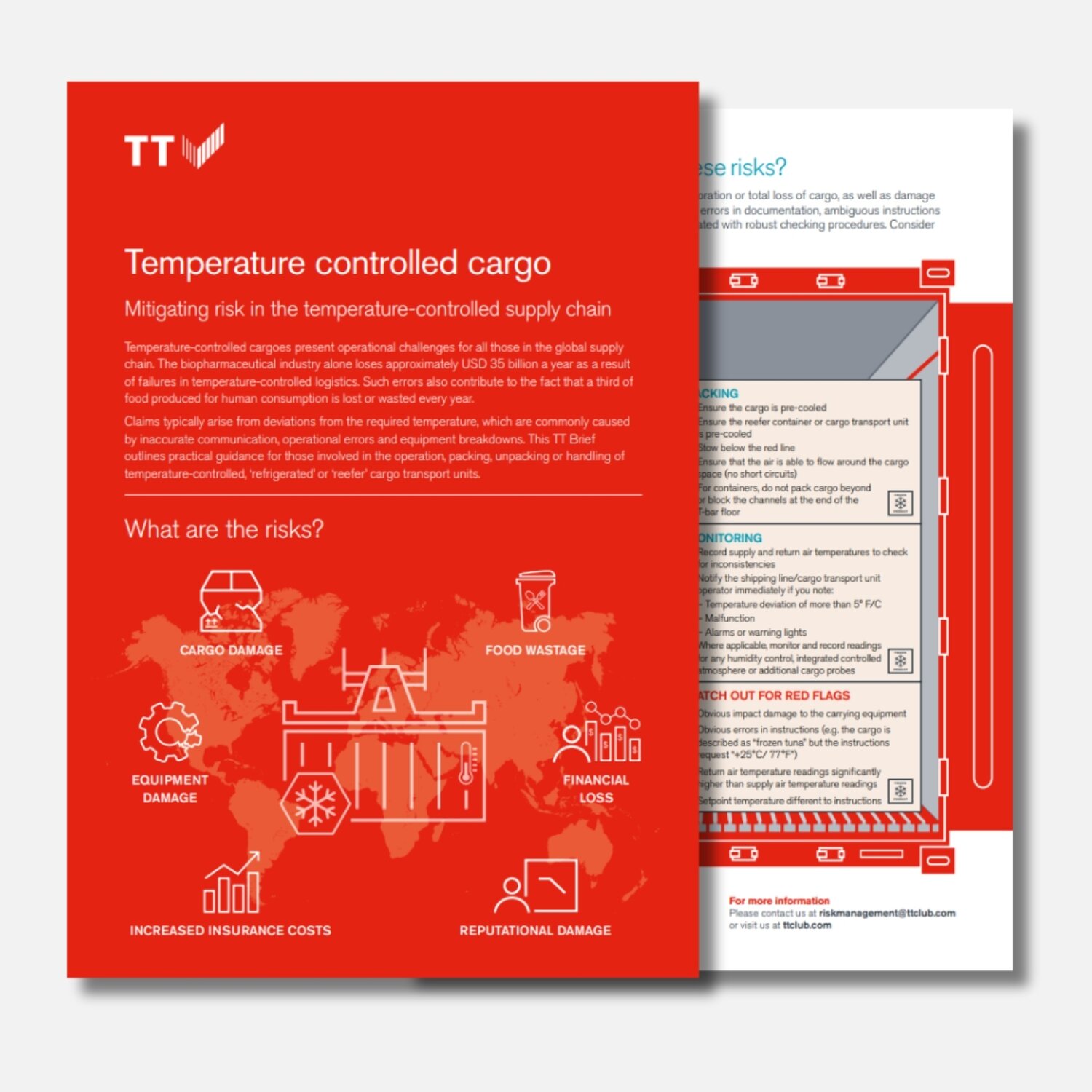

Transporting temperature-sensitive cargo—such as pharmaceuticals, fresh produce, and chemicals—requires precision, vigilance, and robust systems. Even minor deviations in temperature can lead to spoilage, contamination, or regulatory non-compliance.

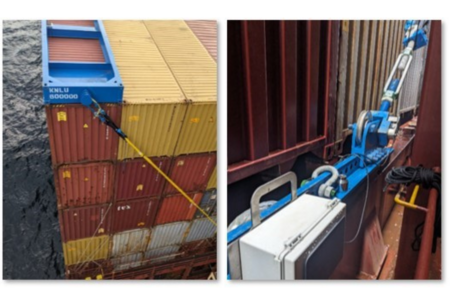

TT Club highlights the critical importance of correct equipment selection, pre-trip inspections, and real-time monitoring to ensure integrity throughout the journey. This page explores common risks, including equipment failure and human error, and outlines best practices for maintaining cold chain reliability. With proactive planning and adherence to standards, operators can protect high-value cargo and minimise exposure to claims and reputational damage.

Get in touch

If you would like more information on any of these topics, submit an enquiry to our Loss Prevention team.

Latest resources

Latest publications

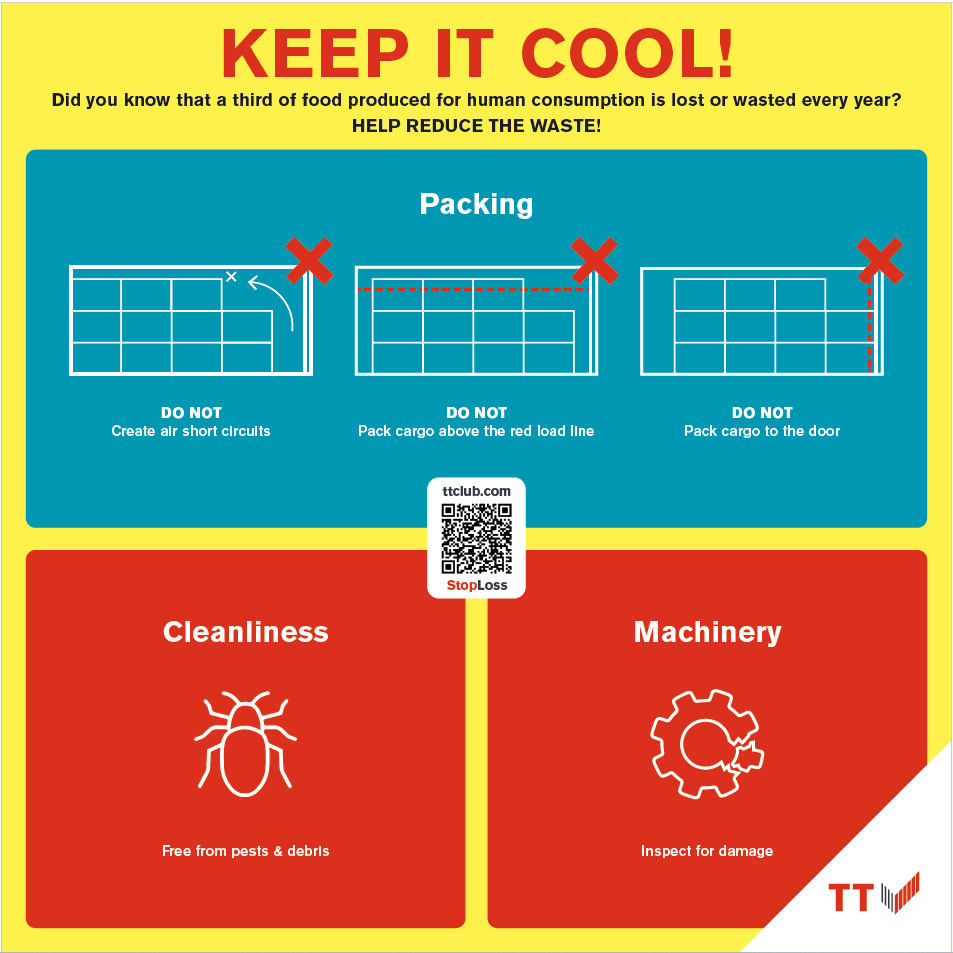

Don't leave it to chance!

Did you know that a third of food produced for human consumption is lost of wasted every year? TT Club's claims data shows that 38% of temperature-controlled cargo loss is due to human errors such as temperature-setting errors and poor packing practices, so why leave it to chance?

We have developed a sticker that can be placed in the container to reduce the risk when transporting temperature-controlled cargo. Click below to access the PDF in both English and Spanish, or reach out to us if you would like the physical stickers.