TT Talk - Safe mooring: focusing on bollards

While the container sector has experienced increase in ship size of some 1,500% over the last 50 years, there have also been significant increases for other ship types, including cruise and car carriers. Regardless of future trends, the risk elements for port operations are writ large. Combining this with changing weather patterns around the globe, safety for navigation and mooring in ports are dynamic issues.

Mooring is essentially the procedure for securing or making fast a ship with a fixed (or floating) object so that the ship is safely confined in a particular location, most commonly to allow for the transfer of people or cargo.

Successful and safe mooring requires a high degree of communication between the ship and landside operatives, all suitably trained, experienced and provided with the correct equipment for the operation. These teams need to have a clear understanding of not only their own role, but also the roles of their counterparts.

Successful and safe mooring requires a high degree of communication between the ship and landside operatives

Although the responsibility of the coordination of the mooring lies with the ship’s Master, there are other key stakeholders:

- Harbour Master

- Pilot

- Port Authority

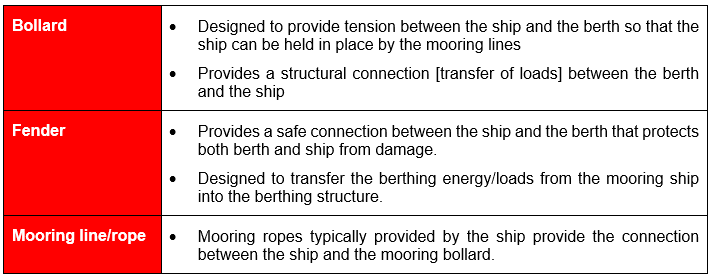

The mooring components required for a connection between the berth and ship are:

Potential risks

Mooring bollards are in common use and face the following risks that could result in their in-service failure:

- Overload resulting from higher than anticipated loads due to larger ships or more extreme weather conditions in the form of high winds or wave conditions;

- Condition deterioration resulting in a lower load capacity from environmental degradation or damage to the bollard from impact or overload; and

- Poor or incorrect installation of the bollard during the original installation resulting from the incorrect torquing of the bolts or poor bedding of the bollard to evenly transfer the loads into the berth.

Considering bollards

Design

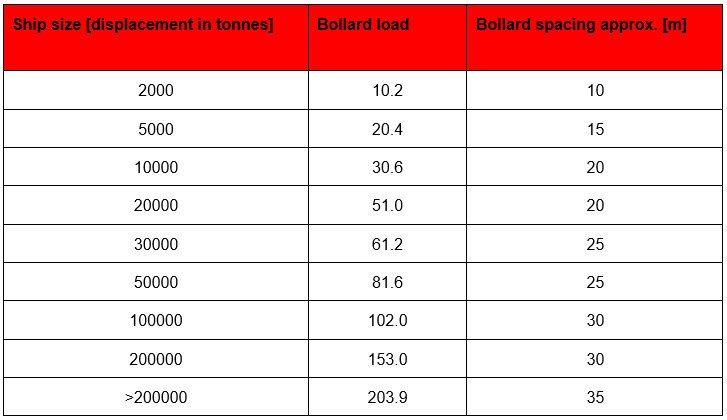

Bollard spacing is typically between 5m and 30m. The load capacity is dependent on the size of ship and design parameters of the given berth. The table below sets out typical spacing and load capacity1. It can be seen that the size of the ship has a significant impact on the required capacity of the bollards and the layout on the berth.

Loads

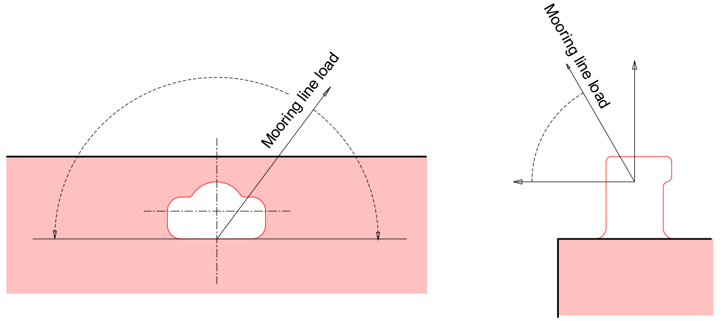

The design of bollards assumes that the mooring line will act in any direction within 180° around the bollard facing the ship and between horizontal and 60° upwards towards the ship as shown below.

Asset management

Bollards are necessarily situated in one of the most exposed parts of the port facility, dealing with often harsh environmental conditions and susceptible to impact damage from quayside operations. Consequently, bollards should be included within a robust inspection and maintenance regime to ensure:

- The bollards remain in serviceable condition; and

- Any incidents [impact or overload] are subject to inspection and verification before being put back into service.

The management of a port’s bollards requires an understanding of both the designed loads and the calculated loads from the ships that will be berthed alongside, ensuring that bollards will not be loaded beyond their Safe Working Load. This requires ongoing review as the size and type of ships accepted by ports change.

Potential pitfall

Mooring bollards are not a “fit and forget” asset. They can be subjected to challenging environmental conditions and increased loading from larger ships during the typically long service life of a berth and its mooring bollards.

Importantly, mooring bollard incidents happen. It is not difficult to see how these assets can get overlooked when managing the numerous and diverse range of assets used within ports and terminals. However, overlooking their deliberate management has the potential to cause significant damage and cost, and even death considering the loads that mooring bollards are subjected to.

Top 3 takeaways

- Bollards are an often under-considered part of the port infrastructure, providing the connection between the ships and the berth. However, when these assets fail in service (under load) the consequences can prove serious due to the release of significant amounts of energy.

- As with any key asset, especially with the forces involved with keeping a ship secured to the berth, effective asset management is vitally important. This should include in-service inspection, maintenance and prevention of overload.

- Post incident, whether it be impact damage or suspected overload, bollards should be inspected by suitably qualified and experienced engineers before further use. You need to be confident that any bollard remains capable of safely accepting the loads expected from berthing ships.

You need to be confident that any bollard remains capable of safely accepting the loads expected from berthing ships

Further learning

TT Club, in association with Port Strategy, has organised a Safe Mooring Seminar on Thursday, 28 March at 90 Fenchurch Street, London EC3M 4ST. This will be an ideal opportunity to listen to a diverse range of experts and innovators raising the challenges and opportunities in mooring, and to network with others with a common interest in improving safety for these vital operations.

Register

1 Data extracted from ICE Port Designer’s Handbook

-

If you would like further information, or have any comments, please email us, or take this opportunity to forward to any others who you may feel would be interested.

Documents

TT Talk Edition 308 (Chinese) (757 kB) 25/03/2024

- Author

- Neil Dalus

- Date

- 05/03/2024