Step 2: Selection of packaging

Having classified the dangerous substances and identified their chemical hazards, it is important for the shipper to ensure that the product is contained within safe and stable packaging.

IMDG Part 4.1 contains the general provisions that define packagings, including intermediate bulk containers (IBCs) and large packagings, suitable for containing dangerous goods.

The key requirements for safe packagings

- Strong enough to withstand the shocks and loadings of transport and all types of handling

- Designed to prevent loss of content owing to variations in pressure, temperature or humidity

- Not be weakened by contact with the product

- Not reactive with the product to cause a dangerous reaction or affect the quality of the product

- In use, the package filler must follow the package manufacturer’s closure procedures so as to ensure effective closure and prevent loss of contents.

For carriage by sea, the IMDG Code requires that packagings (including large packagings, IBCs, tanks and MEGCs) used for dangerous substances and articles must conform to a type successfully tested in accordance with IMDG Part 6, “Construction and testing of packagings”. This provides details on the design and construction of types of packaging, and the individual test standards to which they must conform under the UN packaging testing scheme.

Dangerous substances presented in packaging that is not UN-tested are not acceptable for shipment by sea, unless specifically permitted by the Code. For example, UN-tested packages are not required for goods shipped as Limited Quantities or Excepted Quantities, but the packaging must still meet the general safety provisions of Part 4.

Packagings that have met these standards are conventionally referred to as “UN tested” or “UN approved” packagings.

These standards apply equally to new, reused and reconditioned packagings used for dangerous goods.

Selection of suitable packagings, ensuring any special packing provisions are considered and correct filling of them is the shipper’s legal duty. Packaging selection for individual products within a particular class will vary depending on the chemical nature of the product, and the shipper is required to take that into account when selecting packaging. At all times, unless specifically exempted, the packaging must comply with the general and type-specific UN packaging instructions described in IMDG Part 4.

The shipper’s declaration on the transport document includes a statement certifying that the dangerous goods have been correctly packaged according to the IMDG Code provisions. For example, if a shipper has a liquid product that is corrosive to steel, the packagings he chooses may be steel drums approved for liquids under the UN system for the carriage of liquids, but the shipper must ensure the steel is lined or coated and certified to be resistant to the corrosive nature of his individual product.

Instructions for the correct use of standard packagings such as boxes, drums, jerricans and bags, as well as IBCs, large packagings, pressure receptacles for gases (cylinders and multi-element gas containers), portable tanks and bulk containers and they how shall be used are described Packing Instructions set out in IMDG Chapter 4.1, 4.2 and 4.3 respectively, which describe the uses of packagings.

The majority of entries in the dangerous goods list are assigned packing instructions. These are numbered and shown in separate columns for standard packages and gas cylinders, IBCs, and portable tanks (tank containers) respectively.

- DG List Column 8 indicates Packing Instructions for standard packages such as boxes, drums, jerricans, bags and large packages, providing the range of packaging types that are available to a shipper for the product.

- DG List Column 10 has codes for Packing Instructions for the types of Intermediate Bulk Containers (IBCs) that may be used.

- DG List Column 13 has codes for Tank Instructions for the types of portable tanks or bulk containers that may be used.

IMDG Part 4.1 contains tables listing each Packing Instruction and setting out the details of each one. Where individual substances require specialised or a restricted range of packaging, Packing Provisions are allocated. Packing Provisions are allocated to individual UN Numbers and are attached to the Packing Instruction tables.

For quick reference, the Packing Instructions are arranged as follows:

- Packing Instruction numbers P001 – P911 apply to standard packagings, boxes, drums, jerricans, bags, gas cylinders and packaging for articles such as batteries.

- Packing Instructions IBC01 – IBC08, IBC99, IBC100, IBC520 and IBC620 apply to IBCs.

- Packing Instructions LP01 – LP03, LP99, LP101, LP102, LP200, LP621, LP622, LP902 – LP906 apply to Large Packagings.

- IMDG Part 4.2 contains Tank Instructions and Tank Provisions that define how portable tanks and Multi Element Gas Containers (MEGCs) are used.

- IMDG Part 4.3 has instructions for the use of bulk containers, where no intermediate packaging is used, and the product is packed directly into a cargo transport unit.

Sometimes the nature of an individual substance has special characteristics requiring that packaging is restricted in size, or is qualified or required to be adapted over and above the general standard in order to maintain safety. This is shown in additional Packing Provisions set out in the Dangerous Goods List adjacent to the relevant Packing Instruction as follows:

- DG List Column 9 has codes for Packing Provisions applicable to standard packagings (including large packagings) – boxes, drums, jerricans and bags etc.

- DG List Column 11 has codes for Packing Provisions applicable to IBCs.

- DG List Column 14 has codes for Tank Provisions applicable to tanks, multi-element gas containers and bulk containers.

Articles classified as dangerous goods may not be required to be packaged in UN tested packaging, but the individual entry in the Dangerous Goods List must be checked.

For example, Packing Instruction P003 applies to UN 2800, BATTERIES, WET, NON-SPILLABLE and only requires the batteries to be placed in “suitable outer packagings” that do not need to be UN-tested. However, the Special Packing Provision PP16 applies and requires the batteries to be “protected from short circuit” within the packagings.

In contrast, Packing Instructions P903, P908, P909, P910, P911, LP903, LP904, LP905 and LP906 apply to UN 3090, LITHIUM METAL BATTERIES and require the batteries to be packaged in UN-tested packages meeting the test criteria for Packing Group I (P911 and LP906) and Packing Group II performance level, unless exempted by Special Provisions elsewhere in the Code.

Packagings7 take many forms and may be constructed from a variety of materials or combination of materials. The provisions for these are available in 6.1.4 for conventional packagings, e.g. steel drums, fiberboard boxes, 6.5.1.4 for IBCs and 6.6.2 for large packagings and are summarised below.

Composite packagings

Are made of two or more elements that are designed to be used together and not separated, and may be permanently bonded together e.g. steel drums may have a permanently bonded plastic inner receptacle for extra strength and resistance to the effect of corrosive products, or multi-layer bags or flexible IBCs may have a sift-proof plastic inner liner(s) inside a tear-resistant woven outer layer.

Combination packagings

Are those that have independent removable inner packagings containing the product placed inside an outer packaging that may be fibreboard, wood or plastic, often with shock absorbing and absorbent material between the two elements. Combination packagings are not designed to be opened during transport. Combination packagings are tested with the inner packagings filled with product or comparable substitute inside the outer packaging in the form in which the package will be used.

Construction of a typical combination package for dangerous goods: Separate inner packagings inside a fireboard outer packaging

Boxes

Fibreboard boxes with inner packagings made of plastic for liquids or solids are one

of the most common packagings for dangerous goods.

Boxes may also be made of steel, aluminium or other metal, wood, plywood, reconstituted wood, and solid or expanded plastics, and generally have inner packagings that are in contact with the dangerous goods.

The maximum net mass for different types of boxes varies according to box design and Packing Group. The maximum net mass for a box containing dangerous goods of Packing Group II or III is 400 kg.

Drums

Drums are defined as cylindrical packagings, generally but not necessarily with flat ends. They are produced in a wide variety of sizes and may be manufactured from steel, aluminium or other metal, plastic, plywood or fibre. They may be single packagings, combination packagings with removable inners, or composite packagings with non-removable inner liners.

The maximum net mass for a drum containing any dangerous goods of Packing Group II or III is 400 kg. The maximum net mass for different types of drum varies according to design and Packing Group, and are shown in the individual packing instructions.

Jerricans

Jerricans are defined as rectangular or polygonal packagings and can be up to 120 kg capacity. They are commonly made in smaller sizes, 5 kg up to 30 kg net mass, with carrying handles for convenient manual handling and retail sale.

Handles are frequently moulded into the top of the package, sometimes preventing them from nesting vertically, and care must be taken with some designs when stacking them because they are prone to collapse if over-stowed, and separator boards between tiers to spread the weight are recommended.

Bags

Bags are suitable for some solid dangerous goods of Packing Groups II and III, and they may be made of plastic film, multi-wall paper or woven textile, and can be supplied with a variety of inner linings. They may be up to 50 kg capacity, but 25 kg is more common. Care is needed during manufacture and closure after filling to achieve sift-proof secure stitched seams or welded seams.

Intermediate Bulk Containers (IBCs)8

IBCs are designed for mechanical handling. They can be rigid or flexible and can be up to 3 cubic metres capacity, although the most common are about 1 metre x 1 metre x 1 metre and about 1 tonne gross weight for easy mechanical handling and packing into cargo transport units.

Rigid IBCs are commonly of composite design with a plastic inner receptacle in a metal outer cage. All-metal IBCs can be very robust and be designed for filling or discharging liquids or solids under gravity or pressure. Flexible IBCs are usually made of woven plastic fabric, may be lined with impermeable inner layers and have handles for lifting. Commonly called “big bags” – these are generally certified for one trip only and are non-returnable units.

Reusable metal, rigid and composite IBCs need to be periodically inspected to ensure conformity with design type, internal and external condition and functionality of service equipment. Operators must examine IBCs before they are put into service, then after 2.5 years and after 5 years. Inspection reports must be documented and kept by the owner/operator.

Typical rigid composite IBC

Flexible IBCs

Large packagings9

These are also designed for mechanical handling and are defined as an outer packaging intended to contain articles or inner packagings. They exceed 400 kg net mass or 450 litre capacity but have a volume of not more than three cubic metres.

Large packagings can also be rigid or flexible, with rigid packagings commonly being manufactured from steel, aluminium or other metal and flexible large packagings from plastics or paper.

Refillable receptacles for gases (gas cylinders)10

Individual refillable gas cylinders are marked and labelled with the UN Number and class label in the normal way and may be stowed in shipping containers. Gas cylinders are subject to variable construction and use requirements and are subject to inspection and testing every five or ten years, contingent upon the type of gas – see IMDG Chapter 6.2 for further information.

Pressurised gas cylinders have a unique marking system owing to their specialised construction requirements (they are often suitable for one type of gas only), long working life, and extreme stresses which they must withstand. Shippers should ensure that gas cylinders are subject to the appropriate inspection regime based on the UN system, or an alternative national test regime, acceptable under UN terms.

Internal valves should be effectively closed and designed so they cannot release product as a result of vibration, pressure or temperature change. Removable valves should be detached from the cylinders for transport. Where external cylinder valves are part of the cylinder design, valves should be protected from impact by guards or shrouds. If this cannot be done the cylinders should be packed in frames that provide impact protection for the valves.

-

7 IMDG Code, 2022 Edition Amendment 41-22, Section 6.1.4

8 IMDG Code, 2022 Edition Amendment 41-22, Chapters 4.1 and 6.5

9 IMDG Code, 2022 Edition Amendment 41-22, Section 6.6.4

10 IMDG Code, 2022 Edition Amendment 41-22, Chapters 4.1 and 6.2

With very few exceptions (packagings used for ‘Limited Quantities’ or ‘Excepted Quantities’ consignments being the most notable) dangerous goods transport packagings must be constructed, tested and approved to United Nations (U N) performance standards.

Under the UN packaging specification scheme, samples of a packaging design type are subjected to a series of standard tests – such as being dropped, stacked and subjected to pressure – which simulate predictable transport situations.

The objective is to prove the competence of the packaging design and materials of construction for carrying dangerous goods.

Separate chapters in Part 6 of the IMDG Code describe the testing regime. By way of example, Section 6.1.5 identifies the UN tests which must be carried out on the following packaging types: drums, jerricans, boxes, bags and composite packagings.

Tests must be successfully completed before the packaging can be used for dangerous goods. Once completed a test report and certificate of approval is issued for the packaging design type.

Where a packaging conforms to one or more than one tested packaging design type, including one or more than one tested IBC or large packaging design type, the packaging may bear more than one mark to indicate the relevant performance test requirements that have been met.

Certification can only be granted by a competent authority or an organisation designated for this purpose by a competent authority. The certificate specifies an alphanumeric UN packaging mark similar to the example illustrated left.

The UN packaging mark is subsequently applied by the manufacturer to every packaging made to the tested and approved specification. It identifies certain constraints on the use of the packaging which the consignor must take into account when deciding how to pack the substance being shipped.

But what does this alphanumeric code mean?

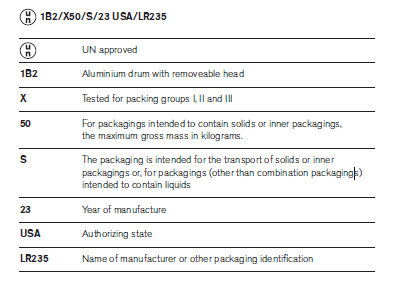

Markings for packagings11

Examples of the alphanumeric UN packaging marks used to identify a number of common packaging types are illustrated and explained below.

Steel drum – 1A1

The first ‘1’ identifies the packaging as a drum and the ‘A’ identifies it as being made from steel. The second ‘1’ identifies that this is a non-removable head drum.

Plastics drum – 1H2

The ‘1’ identifies the packaging as a drum and the ‘H’ identifies it as a plastics drum. The ‘2’ identifies that it has a removable head drum.

Fibreboard box – 4G

The ‘4’ identifies it as a box and the ‘G’ identifies it as being made from fibreboard.

Further information on the codes used for different packagings can be seen in Section 6.1.2.

Example packaging mark:

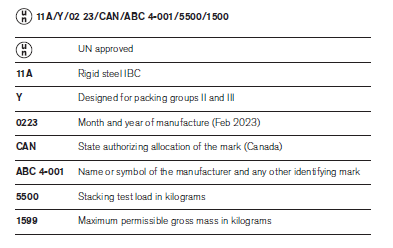

IBC and large packagings marking12

A similar marking system is used for IBCs and large packagings that have been manufactured to a UN tested and approved design specification. The packaging code options used for IBCs are:

- rigid, identified by the numbers ‘11’ and ‘21’ for solids, and ‘31’ for liquids; or

- flexible, identified by the number ‘13’.

This number is combined with a code identifying the material(s) of construction. For example, the code for a rigid IBC made from steel and designed to carry a liquid is 31A (‘31’ for ‘rigid for liquids’ and ‘A’ for ‘steel’).

Example IBC packaging mark:

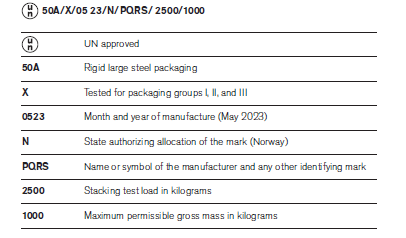

Full details of the applicable markings can be found in 6.5.2. For large packagings there are only two packaging codes used:

- 50–Rigid

- 51 – Flexible

Example large packaging mark:

Full details of the applicable markings can be found in Section 6.6.3.

-

11 IMDG Code, 2022 Edition Amendment 41-22, Sections 6.1.2 and 6.1.3

12 IMDG Code, 2022 Edition Amendment 41-22, Sections 6.5.2 and 6.6.3