Step 5: IMDG segregation

IMDG Part 7 predominantly looks at stowage and segregation of dangerous goods both within a CTU and between CTUs onboard a ship.

Here though we focus on segregation within in a CTU as this is one of the major considerations when packing containers.

Segregation in the context of the IMDG Code is the process of separating two or more dangerous substances or articles which are considered mutually incompatible when their packing or stowage together may result in undue hazards in case of leakage or spillage, or any other accident.

Segregation can be considered in terms of:

- between packages on deck, within the hold of a ship or loaded inside a CTU;

- between packages and CTUs; or

- between CTUs.

As far as cargo packers are concerned, this means not packing incompatible dangerous goods in the same cargo transport unit; for ship stowage planners it means stowing cargo transport units containing incompatible dangerous goods in different parts of the ship to prevent a dangerous reaction between the contents of the different CTUs.

There are instructions in IMDG Chapter 7.2 for calculating the rules for determining which dangerous goods are prohibited in the same shipping container and which may be packed together.

In the following sections we focus on segregation within a CTU and the process the packer must follow when packing different dangerous goods into the same CTU.

There are two key points at which a segregation check must be carried out. The first should be carried out by the shipper before offering a multiple hazard cargo, and then when a packer is preparing to pack multiple hazard cargoes into a single cargo transport unit.

A shipper offering different types of dangerous goods in the same consignment needs to determine if the goods can be packed in the same cargo transport unit. However, if the shipper sends his dangerous goods to a consolidator he has no control over what is packed into the cargo transport unit. It is always the party who is in charge of packing the unit who must carry out the definitive segregation check.

Packers consolidating dangerous goods of different types into a cargo transport unit for several different shippers need to carry out a segregation check between each of the proposed dangerous goods items before packing commences as it is their responsibility to sign the container packing certificate that attests, amongst other things, that the IMDG Code segregation requirements have been followed.

The only method of ensuring compliance is to follow the IMDG segregation rules although there are different options for doing this:

IMDG Code books

Train staff to consult the segregation rules in IMDG Chapter 7.2 and follow the rules manually. This requires a basic understanding of classification as well as knowledge of the segregation process. It can become complex when there is a high number of dangerous goods items being shipped together in the same cargo transport unit.

Online validation systems

The often complex nature of applying the IMDG Code segregation rules can be assisted via computer based or online validation tools. UN Numbers are fed into the program and an IMDG Code compliance/non-compliance report can be automatically generated.

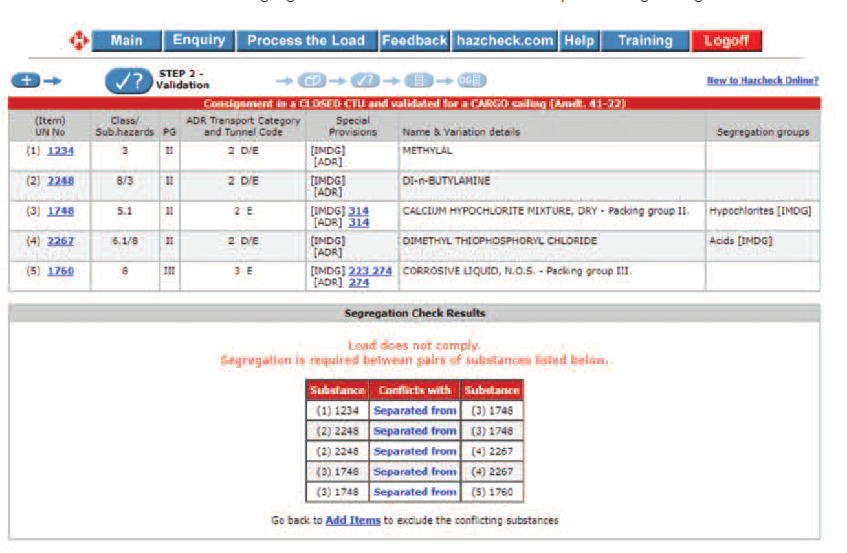

Hazcheck Systems produced by Exis Technologies provide a number of solutions to assist with IMDG Code validation including complex segregation calculations. Further details can be found at https://existec.com/product-category/hazcheck/validate/ . The screenshot below is taken from Hazcheck Online and highlights the validation results for an incompatible dangerous goods load:

Computerised systems like this are useful in calculating segregation, but users are required to be familiar with the software as well as understand the IMDG Code segregation process.

Software embedded in the shipping line booking system

Shipping lines frequently have IMDG Code software embedded into their booking systems to assist in identifying segregation errors at the booking stage. This allows errors to be quickly picked up before the shipment enters the transport stage.

The following outlines the main considerations when checking segregation for a mixed load of dangerous goods items.

Identify and gather all the dangerous goods details

To carry out a segregation check you will need to gather the UN Numbers, the classes, sub-hazards, and packing groups of the dangerous goods to be packed, and for N.O.S. whether or not they have a segregation group applied.

Check the segregation requirements between classes and sub-hazards

First check the compatibility between the classes of dangerous goods. Some classes are incompatible with others, and must never be packed in the same shipping container.

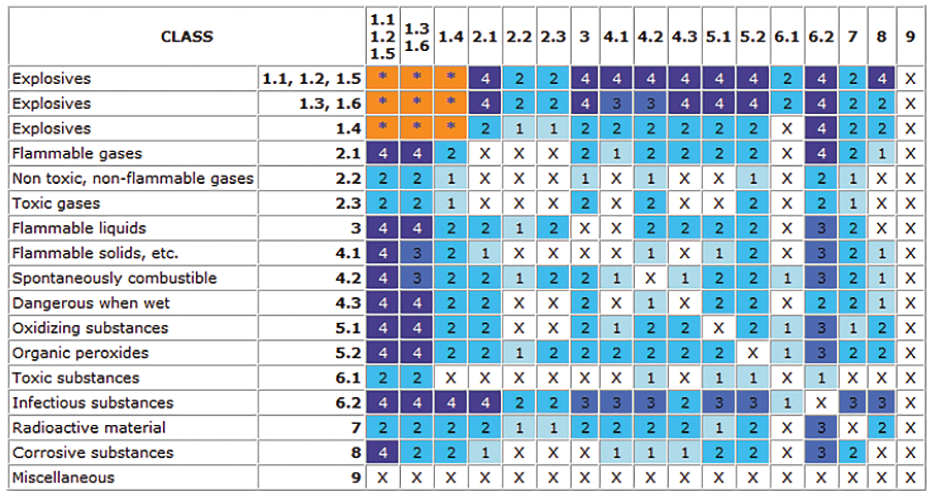

If a substance has a sub-hazard, that must also be checked for segregation restrictions against other classes and other sub-hazards in the same way as the main hazard class. In order to do this table 7.2.4 of the IMDG Code, shown below, must be used.

The numbers and symbols in the table have the following meanings:

1 – “away from”

2 – “separated from”

3 – “separated by a complete compartment or hold from”

4 – “separated longitudinally by an intervening complete compartment or hold from”

X – the Dangerous Goods List has to be consulted to verify whether there are specific segregation provisions

* – see 7.2.7.1 of this chapter for the segregation provisions between Class 1 substances or articles

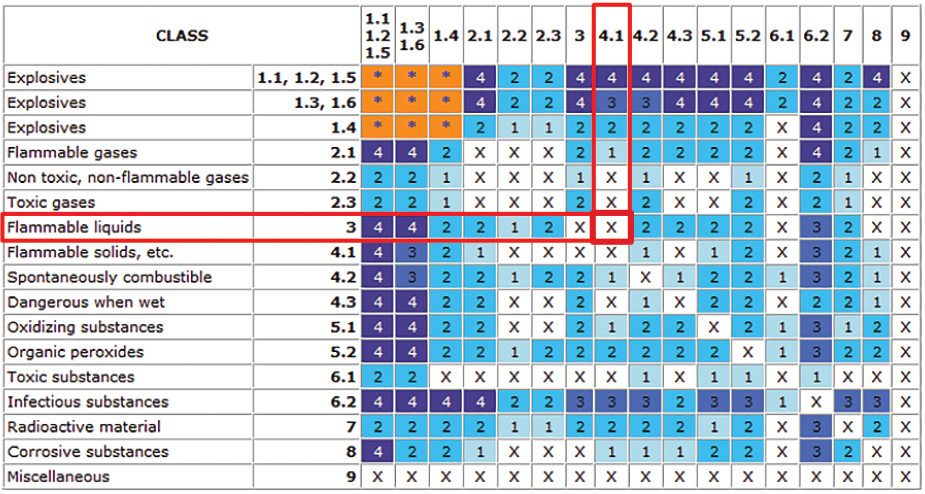

Let’s look at an example of how this is applied and see if a Class 3 substance can be shipped together with a Class 4.1 substance. Using table 7.2.4 we see the following:

Since the two classes line up with an “x” in the crossover box this means that they are compatible at general class and sub-hazard level, and may be compatible to be packed in the same cargo transport unit.

If a 1, 2, 3, or 4 were displayed in the crossover box, this would mean that substances were not compatible and the segregation process stops there.

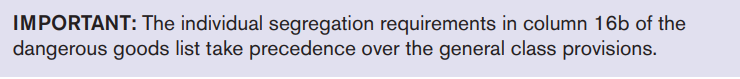

However, as the properties of individual substances and articles within each class may vary greatly, the Dangerous Goods List, column 16b, must also be consulted for particular provisions for segregation. Individual substances may be incompatible with a substance of another class, or incompatible with substances in the same class as itself.

Check for specific segregation requirements in column 16b of the dangerous goods list

As well as checking the generic class segregation requirements in 7.2.4 you must also check if there are any specific segregation requirements in column 16b. These segregation requirements will be referenced via either:

Segregation group code(s) as per 7.2.5; and/or

Segregation code(s) as per 7.2.8.

If there are no class segregation clashes found in 7.2.4 it is important to check that there are also no specific segregation clashes arising from these two additional requirements. An example of how these appear in the dangerous goods list is shown below:

The meaning of these codes can be found in 7.2.5 (segregation group codes) and 7.2.8 (segregation codes). From our examples above:

UN 2714 – SGG7 – Heavy metal compound

UN 2716 – SG35, SG36 and SG55 –

SG35 Stow “separated from” SGG1 – acids

SG36 Stow “separated from” SGG18 – alkalis

SG55 Stow “separated from” mercury salts

UN 2719 – SGG3, SG38 and SG49 –

SGG3 – Bromate

SG38 Stow “separated from” SGG2 – ammonium compounds

SG49 Stow “separated from” SGG6 – cyanides

But what does this means in terms of segregation?

For UN 2714 this means that presence of SGG7 identifies this as belonging to segregation group 7, heavy metal compounds. If this is stowed in a CTU with any other substance or article that requires segregating from heavy metal compounds then there would be clash and these items must be segregated i.e. not stowed in the same CTU.

For UN 2716, there are a number of additional segregation requirements to consider. If this substance is loaded in the same CTU as any other DG identified as being a ‘acid’, ‘alkali’ or ‘mercury salt’ then this substance must be separated from that DG.

For UN 2719, this substance is a member of segregation group 3, bromates so if it stowed in a CTU with any substance or article that must be segregated from bromates there would be a clash and the two items must not be stowed in the same CTU. In addition, this commodity must also be separated from ‘ammonium compounds’ and ‘cyanides’, so any DG loaded in the same CTU belonging to either of these two segregation groups must also not be stowed in the same CTU.

There are 18 segregation groups36 in total, all of which are listed below (with the relevant code that appears in column 16b in brackets):

- Acids (SGG1)

- Ammonium compounds (SGG2)

- Bromates (SGG3)

- Chlorates (SGG4)

- Chlorites (SGG5)

- Cyanides (SGG6)

- Heavy metals and their salts (SGG7)

- Hypochlorites (SGG8)

- Lead and its compounds (SGG9)

- Liquid halogenated hydrocarbons (SGG10)

- Mercury and mercury compounds (SGG11)

- Nitrites and their mixtures (SGG12)

- Perchlorates (SGG13)

- Permanganates (SGG14)

- Powdered metals (SGG15)

- Peroxides (SGG16)

- Azides (SGG17)

- Alkalis (SGG18)

There are 78 segregation codes37, an example of some of these is supplied below:

Segregation is more problematic for N.O.S. substances used for generic entries, mixtures, solutions and preparations. The technical names that comprise this N.O.S. shipment might properly belong to segregation groups. If an N.O.S. substance has significant components that are in a particular segregation group, it would be likely that the N.O.S, substance should be included in that segregation group for the purposes of segregation, and if so, the shipper should allocate a segregation group and mention it on his shipper’s declaration on the transport document.

There are instances where dangerous goods must be separated from foodstuffs 38. This affects dangerous goods having a primary or subsidiary hazard of classes 2.3, 6.1, 7 (with the exception of UN 2908, 2909, 2910 and 2911), 8 and dangerous goods for which it is referred to in segregation code SG29 or SG50 in column 16b of the DGL, stowed in a conventional way, must be “separated from” foodstuffs stowed in a conventional way.

If either dangerous goods or foodstuffs are in a closed CTU, the requirement reduces to “away from”.

If both dangerous goods and foodstuffs are in different closed CTUs, no segregation requirements apply.

Dangerous goods of class 6.2 stowed in a conventional way must be “separated by a complete compartment or hold from” foodstuffs stowed in a conventional way. If either dangerous goods or foodstuffs are in a closed cargo transport unit, dangerous goods must be stowed "separated from" foodstuffs.

-

38 IMDG Code, 2022 Edition Amendment 41-22, Section 7.6.3.1

There are a number of special segregation provisions and exemptions from the segregation requirements. These include:

- Exemptions from taking into account conflicting subsidiary hazards if the substances are proven not to react dangerously with each other39

- Exemptions for chemically similar substances40

- Exemptions for class 8 acids and alkalis meeting certain conditions41

- Exemptions for dangerous goods in ‘limited quantities’ or ‘excepted quantities’ provided they do not react dangerously with each other42

-

39 IMDG Code, 2022 Edition Amendment 41-22, Section 7.2.6.1

40 IMDG Code, 2022 Edition Amendment 41-22, Section 7.2.6.3

41 IMDG Code, 2022 Edition Amendment 41-22, Section 7.2.6.5

42 IMDG Code, 2022 Edition Amendment 41-22, Sections 3.4.4 and 3.5.8