TT Talk - LNG bunkering considerations

Significant coverage has been given to the debate in the maritime world concerning Sulphur content in bunker fuel and reduction is CO2 emissions. One fuel solution is LNG, but what are the implications for the shoreside infrastructure?

LNG has grown in popularity as fuel for the ships, especially for use within the increasing number of emission control areas (ECA). As a result, port authorities and terminal operators, notably across Europe, are facing an issue of which method of LNG bunkering should be chosen to offer to ships. This problem extends beyond those ports which are obligated to provide such services, according to European and national regulations for TEN-T network, and the pure accessibility of alternatives fuels. Indeed, some ports may consider building LNG bunkering facilities in order to attract ships powered by LNG, as well as their cargoes.

Evaluating methods of implementation

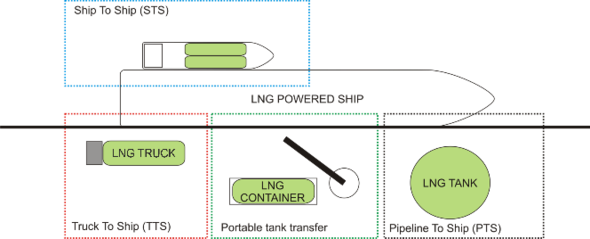

There are four methods of bunkering LNG (see Fig 1):

- LNG tank container;

- truck to ship;

- terminal to ship; and

- ship to ship

Fig 1 Methods of bunkering (source MarTech LNG brochure)

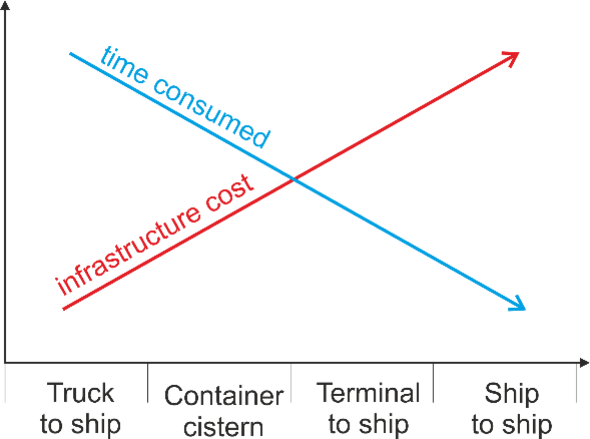

All of these have strong and weak points, particularly in relation to time consumed and infrastructure cost (see Fig 2).

Fig. 2 Functions of infrastructure cost and time consumed for transfer of LNG

The least infrastructure investment is required in case of the truck to ship method and use of a tank container, but the transfer of LNG is slow. It is possible to increase the rate of transfer by connecting more tank containers into a hub installed on a berth, but that requires increased space for truck maneuvering and an enlarged safety zone. The use of tank containers can be effective – loaded by crane or roll-on – but only for ships where the fuel is deployed from the tank containers rather than ship-board tanks. Both of these methods occupy a space on a berth and require safety procedures that may be impossible in the context of the physical environment and cargo or other operational requirements.

Planning a small scale LNG terminal requires building a storage tank and a transferring infrastructure. The storage tank can be located in a distance from the bunker berth, which may be beneficial for safety since it segregates the LNG infrastructure and the ship from cargo operations. Furthermore, this method can be used in ports where the berth construction is light and would not bear the weight of heavy tanks. Dependent on the size (LNG volume) of such a terminal, there are possibilities for the operation to be handled by few persons or even fully automated, leaving the ship’s crew responsible for bunkering operations, monitored remotely by the supplier.

The most flexible, but most expensive, method of LNG bunkering is deploying a bunker barge. However, aside from capital and operational costs, this method has only positives. This ship-to-ship method avoids on berth construction and space constraints. It also does not impede cargo operations because the bunkering operations and safety zone are held on the sea side. Furthermore, there is greater flexibility since the barge can serve all berths in a port. Additionally, fuel delivery to the barges can be made through other facilities, not impacting directly on port cargo operations at all.

Key considerations

Ports authorities and terminal operators should consider the following issues when deciding on the LNG bunkering method:

- type of the ships, frequencies of bunkering, volume of LNG per ship, available time for bunkering etc.

- availability of berths - permissible loads, port infrastructures and appropriate safety procedures

- distance to the source of LNG

- possibilities of cooperation with other ports

- dimensions of safety zones

The table below presents key properties of above mentioned methods.

Summary table of bunkering considerations

| Tank container | Truck to ship | Terminal to ship | Ship to ship | |

| Investment cost | Nil | Nil or low | Significant | Significant |

| Operational cost | Nil | Nil | Moderate | Significant |

| Transfer rate | Dependent on container exchange | 40 t/h (dependent on balance between size of hub & available space) | 200 t/h | 300 t/h |

| Safety zone | N/A | On berth side, impact on cargo operations; simultaneous operations may be prohibited | On berth side; impact on cargo operations; simultaneous operations may be prohibited | On sea side only; no impact on cargo operations |

| LNG availability | Limited to berths equipped with a vertical or horizontal loading system and permissible loads of the berth | Limited to space and permissible loads of the berth | Limited to the berth with the LNG bunker installation | Range of bunker barge |

| LNG handling | Only a crane or a terminal tractor operator | A truck driver preparing the installation on the shore side (passes LNG hose to ship's crew or connect to a hub) | Terminal personnel preparing installation before ship’s arrival. In case of small installation it can be fully automated and operated by ship’s crew | Bunker barge crew responsible for preparing installation for bunkering |

We gratefully acknowledge the assistance in the preparation of this article of Dr Eng Stefan Jankowski, Maritime University of Szczecin.

- Author

- Staff Author

- Date

- 06/11/2018